420 Stainless Steel (UNS S42000) by Vulcan Metal Group

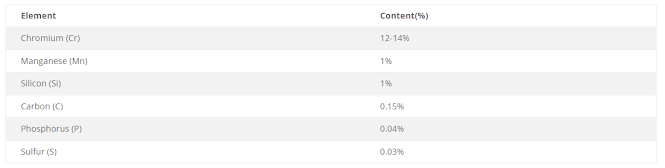

Grade 420 stainless steel is high-carbon steel. Chromium is added to a minimum content of 12%. Grade 420 is ductile when annealed and has excellent corrosion resistance when polished or hardened. The following datasheet gives an overview of 420 stainless steel. Chemical Composition Physical Properties Mechanical Properties Thermal Properties Fabrication and Heat Treatment Machinability When annealed, 420 steel is easily machinable. Welding Use welding rods coated with grade 420 metals for high-strength joints. For ductile joints, use grade 309 filler rods. Heat Treatment Annealing: Heat at 840° to 900°C. Slow furnace cool @ 600°C, then air cool. Process Anneal : A nneal at 735°C to 785°C. Air cool. Hardening: Heat at 980°C to 1035°C. Air or oil quench. Temper at 150°C to 370°C for high hardness and good mechanical properties. Applications Grade 420 stainless steel is used in the following applications: Shear blades Needle valves Surgical equipment Cutlery See more..